Precision without compromise: Rethinking what's possible in Differential Oscillators

For years, timing engineers have faced an uncomfortable truth: if you needed the cleanest possible clock signal for high-speed applications, you had to make room for it. Ultra-low jitter performance came in larger packages. Compact oscillators meant accepting higher phase noise. It was always a trade-off. Until now.

The high-speed design dilemma

Walk through any modern data centre server, AI accelerator board, or high-speed optical module, and you'll see the same challenge playing out: every square millimetre matters. PCIe Gen5 implementations need 16 or more differential lanes. 100G and 400G optical transceivers pack extraordinary functionality into QSFP-DD and OSFP form factors. GPU and AI accelerator cards cram massive compute density into standard PCIe card dimensions.

At the same time, the timing requirements have never been more stringent. A PCIe Gen5 interface running at 32 GT/s can't tolerate sloppy reference clocks. A 25G optical SerDes needs sub-50 femtosecond jitter to maintain bit error rates. Multi-gigabit FPGA implementations demand clean, stable differential clocks to keep high-speed transceivers locked.

The conventional wisdom said you couldn't have both. Choose your priority: ultra-low jitter in a 3.2×2.5mm or a larger package or accept degraded performance to fit into something smaller.

Breaking the compromise

The new GXO-95 family of differential crystal oscillators fundamentally changes this equation.

At just 2.0×1.6×0.7mm, these are among the smallest differential XOs available for high-performance applications. But here's what makes them different: they deliver 0.04 ps typical phase jitter (12 kHz–20 MHz integration bandwidth) from production silicon. That's not "pretty good for the size." That's world-class jitter performance in any package size.

This is precision without compromise.

Three solutions for every high-speed application

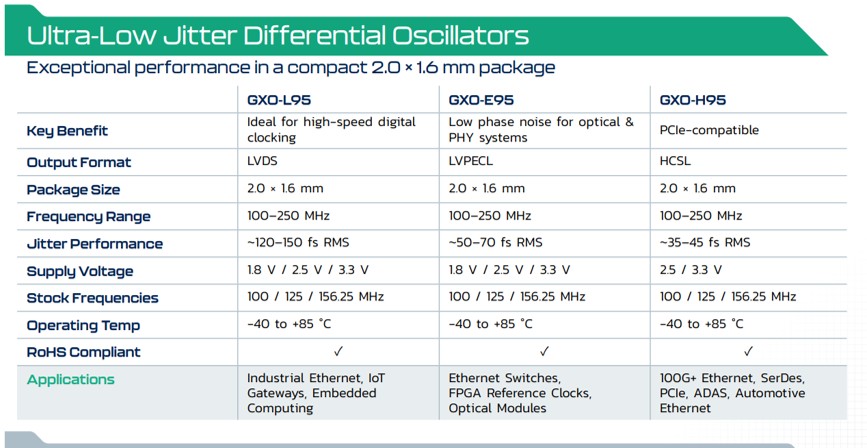

The GXO-95 family covers the three most critical differential output types in modern system design:

GXO-L95 (LVDS Output)

Purpose-built for SerDes and FPGA clock trees, the LVDS variant targets networking equipment, industrial systems, and computing applications where multi-gigabit serial links are standard. LVDS's low power consumption and proven EMI performance make it ideal for multi-clock systems.

GXO-E95 (LVPECL Output)

High-speed optical networking and 10G/25G PHY implementations demand the proven performance of LVPECL signaling. The GXO-E95 delivers the rail-to-rail differential swing and fast edge rates that optical module designers and test & measurement engineers rely on.

GXO-H95 (HCSL Output)

PCIe reference clocking has standardized on HCSL for good reason - it's optimized for the low-jitter, low-power requirements of modern server and accelerator designs. The GXO-H95 provides the clean 100 MHz reference that PCIe Gen4 and Gen5 controllers need, whether you're designing SSD controllers, GPU cards, or AI inference boards.

All three variants share the same compact 2.0×1.6mm footprint, 100–160 MHz frequency range, and support for 1.8V, 2.5V, and 3.3V supply voltages. Industrial temperature options are available across the family.

Real-world impact: More than just size

The immediate benefit is obvious: you get back precious board space. On a dense AI accelerator with 16 PCIe Gen5 lanes, replacing larger reference oscillators with GXO-H95 variants can free up routing channels, simplify power distribution, or simply make a previously impossible layout work. But the implications go deeper.

Simplified BOM Management: Three output types, one compact footprint. Your procurement team can standardize on a single package size across multiple applications, reducing inventory complexity and qualifying just one footprint for multiple designs.

Layout Flexibility: Smaller oscillators mean more options for placement. That critical reference clock can now sit closer to the PHY it's serving, reducing trace lengths and improving signal integrity. Or it can tuck into a space that was previously unusable.

Thermal Management: Less board area consumed by timing components means more room for thermal solutions where they matter most—on processors, power stages, and optics.

Future-Proofing: As system speeds continue to increase (PCIe Gen6, 50G/100G SerDes, 800G optics), having timing sources that exceed current requirements gives you headroom for the next generation.

Built on Proven Technology

The GXO-95 family is based on the OO-U differential oscillator platform, which brings years of field-proven reliability to this new compact form factor. This isn't an experimental technology or a compromise solution - it's advanced crystal resonator technology, precision analog design, and rigorous manufacturing standards applied to a package that meets modern density requirements.

Every oscillator is fully tested for frequency accuracy, jitter performance, and supply voltage tolerance before shipping. All published specifications reflect measured performance from qualified production devices. Standard screening includes frequency stability over temperature, output signal integrity verification, and phase noise characterization.

Who should be paying attention

If you're designing any of these systems, the GXO-95 family deserves a closer look:

Server and Data Center Equipment: PCIe Gen4/5 reference clocks that don't dominate your board layout

AI and ML Accelerators: Timing for high-speed interconnects in power- and space-constrained designs

Optical Networking: 10G, 25G, and 100G module clocking in compact form factors

High-Speed Test Equipment: Precision reference clocks for signal generation and analysis

Industrial and Embedded Systems: Reliable differential timing for ruggedized, space-constrained applications

The no-compromise era

For too long, timing engineers have been forced to choose between the specs they need and the footprint their layouts demand.

The GXO-95 family proves that compromise isn't necessary. 0.04 picoseconds of jitter (12 kHz–20 MHz). 2.0×1.6 millimeters of board space. Three industry-standard output types. This is what precision without compromise looks like.

Ready to see what's possible in your design?

Request evaluation samples of the GXO-95 family, download complete technical specifications and application notes, or speak with our timing specialists about your specific requirements.

Contact the TechPoint Golledge team on 0333 996 3664 or email sales@golledge.com